Natural polymers: a new solution for sustainable packaging

Irene Ríos, Packaging researcher, AIMPLAS

The packaging production industry is a major consumer of materials, especially plastics. In fact, 42% of the world’s plastic is used to package food and manufactured products. It naturally has environmental impacts due to extraction and use of these materials and because of the waste generated during processing and especially once the packaging has reached its end of life. This means that waste is either treated by incineration processes or disposed of in the environment.

Another current problem with plastic packaging is that it is difficult to recycle, especially single-use packaging made of conventional plastics from fossil fuel sources. These small packaging items are often difficult to include in recycling processes, thus preventing their return to the cycle of recycling and reuse.

Changes to current legislation are now taking place as a result of these issues and the environmental impacts associated with plastic packaging not disposed of in recycling bins. This includes Law 7/2022 on waste and contaminated soil within the framework of a circular economy, as well as the implementation of the single-use plastics (SUP) directive. Broader initiatives are also being implemented, such as the transition to a circular economy promoted by the European Green Deal and the European strategy to ensure that all packaging is designed to be recyclable or reusable by 2030.

Although the use of biopolymers and biodegradable, compostable and soluble polymers is steadily increasing as a more sustainable version of commonly used plastics, further developments are still needed to produce packaging that complies with current regulations. In cases such as the SUP Directive, most of the materials just mentioned do not comply with the parameters of this regulation because the thermoplastic materials currently in use generally require chemical modification processes.

This is where packaging based on natural biopolymers could offer environmental benefits as a sustainable alternative to packaging made from conventional materials. The use of these bio-based materials provides not only an environmental benefit, but also a means of product differentiation and a way to satisfactorily comply with new legislative demands by proposing suitable and promising packaging with properties like those of conventional packaging.

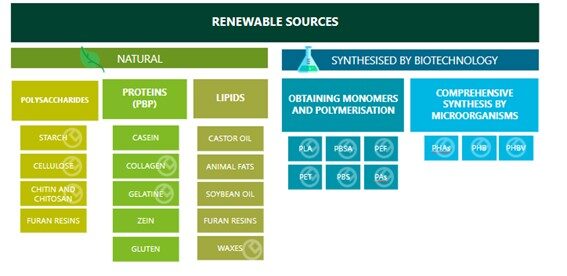

Below is a diagram of natural biopolymers, which shows that biopolymers, i.e. polymers found in nature, can be of both natural and of synthetic origin. The main difference between natural and synthetic biopolymers is their origin and chemical composition.

Moreover, compostable solutions are not exempt from payment of the recent plastic tax because they are considered to be chemically modified plastic materials, even though their end of life is more sustainable. The alternative of using physically modified natural polymers is therefore gaining ground in these applications, given that they are accepted by the SUP Directive and come from renewable sources. They are also biodegradable in different media, including soil and water.

These new materials must have suitable characteristics to be used in conventional packaging processes, such as injection moulding and extrusion. Plasticizing techniques of natural polymers, based on plastic compounding, therefore make it possible to develop new grades of plastic that meet the requirements of the injection moulded packaging industry.

The new materials can come from different natural sources such as algae, starch, meat and milk, among many others. Natural polymers are often extracted from the by-products of different industries, mainly the food industry, thus giving these low-cost materials added value, which makes them perfect candidates for sustainable packaging applications and also suitable under current single-use packaging legislation.

As a result of this problem and these new scenarios, the OCEANIDE Project was set up with the main objective of developing compounds based on natural biopolymers to create innovative food packaging that meets traditional standards and complies with new legislation.

The consortium members working to attain the project goals are the Universidad de Estudios Generales de Valencia (UVEG), which validates project developments from studying the compatibility of food contact plastic, and ALMUPLAS, which validates materials at an industrial plant and obtains injection moulded packaging for different products.

This project aims to obtain a set of results that can be summarized as follows:

- To achieve natural polymer formulations suitable for use in transformation processes such as thermoplastic injection moulding.

- To create disposable packaging and validate its functionality for use for takeaway foods such as ice cream and spreadable sausage and cheese.

- To design packaging with a reduced environmental impact that is soluble in both salt and fresh water, highly degradable and does not generate waste in the environment.

- To offer cost-competitive packaging. This inexpensive packaging is made from natural biopolymers, often from the food industry. It also complies with current legislation for single-use packaging and is exempt from new plastic taxes and Ecoembes green dot fees.

The OCEANIDE Project thus aims to combine different natural polymers from different sources (mainly polysaccharides and proteins) to offer performance levels similar to those of conventional plastics. Different properties will be assessed during this process, such as viscosity, heat resistance and mechanical strength, as well as suitability for food contact to meet resistance to fat and freezing requirements. These new materials will provide a wide range options that can be easily industrialized to achieve market-ready developments that are quickly adopted by companies.

Natural source/waste: raw material

Natural polymer

Packaging: ice cream and spreadable deli tubs

In order to achieve the proposed goals, formulations are being studied and developed in the first period of the project based on plasticization of natural polymers using compounding technology. Different thermoplastic processing equipment is being used for this purpose, including torque rheometers and co-rotating twin-screw extruders, to assess different processing conditions and obtain a range of results in terms of appearance, processability and composite properties.

To obtain packaging prototypes from the compounds obtained, laboratory scale tests are being carried out using injection moulding processes with the aim of obtaining test specimens and studying the mechanical properties of the different formulations so that, in a subsequent stage, the formulations can be studied again, this time using pilot plant equipment to obtain prototype packaging. Tests can then be performed on the final specimen. In the second stage, tests will focus on the injection of optimized composites obtained in an industrial environment. Finally, a physicochemical validation of the food packaged in the test specimens will be carried out, as well as a physical and mechanical validation of the prototypes and a validation of suitability for food packaging in order to corroborate compliance with the specifications required of the final application

The OCEANIDE Project is part of the call for proposals of the Valencian Innovation Agency (AVI) with a duration of 24 months and ending in October 2024.

As a plastics technology centre, AIMPLAS has the capacity, knowledge and experience to obtain new thermoplastic compounds, based on natural polymers without chemical modification, that can be processed using conventional plastic transformation technologies.